Steel Roof Tile Production Line

| Machine Description | Quantity | Delivery time | Container Type |

| steel roof tile production line | 1 SET | 45 working days after receiving deposit | One 20GP |

Roof panel are widely used in building: the steel-structured large-scale warehouses, plants, supermarkets,

shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and

different kinds of greenhouses. What's more, equipment can be designed and manufactured as customers'

requests.

steel roof tile production line Production Process:

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Auto cutting→Products

receiving

Details of steel roof tile production line:

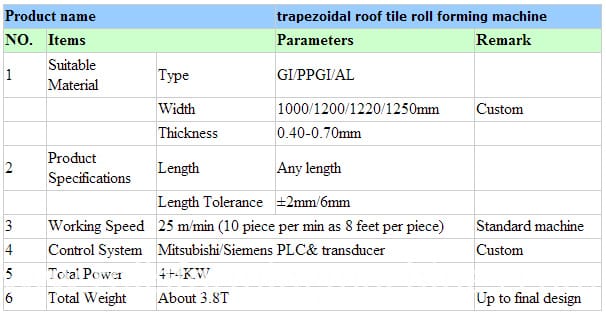

Parameters of steel roof tile production line:

More photos of steel roof tile production line:

Raw materials of trapezoidal roof tile forming machine

Packaging Detail of trapezoidal roof tile forming machine:

1. One 20ft container for loading one set machine with Manual Decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Looking for ideal Trapezoidal Roof Tile Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Trapezoidal Roof Production Line are quality guaranteed. We are China Origin Factory of Trapezoidal Tile Production Line. If you have any question, please feel free to contact us.

Product Categories : Roofing/ Wall Panel Sheet

Mr. Cary xu

Mr. Cary xu