Roof and Wall Panel Roll Forming Machine

Roof and Wall Panel are widely used in building: the steel-structured large-scale warehouses, plants, supermarkets,

shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and different kinds of

greenhouses. What's more, equipment can be designed and manufactured as customers' requests.

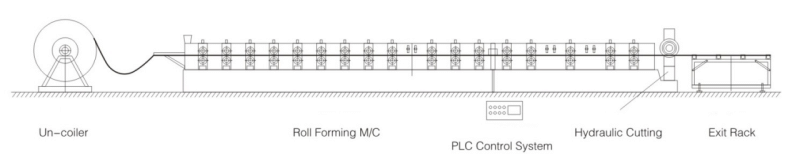

Roof and Wall Panel Roll Forming Machine Production process

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Auto cutting→Products

receiving

With the work process of roof and wall panel roll forming machine, we will provide other accessories like

one set Manual Decoiler, one set PLC control station, one oil pump and one set product collect table.

The accessories photos of Roof and Wall Panel Roll Forming Machine

Raw Materials

| Equipment and Qty. |

| Decoiler | 1 set |

| Main roll forming machine | 1 set |

| PLC control station | 1 set |

| Hydraulic station | 1 set |

| Post cut | 1 set |

| Electric motor | 1 set |

| Runout table | 1 set |

Parameter of Roof and Wall Panel Roll Forming Machine Processing material: colored steel plate, galvanized plate.

Material thickness: 0.3- 0.8 mm

Material hardness: 195 mpa---350 mpa

Formed width:1015 mm

Forming speed: 12 m/min Loading capacity:5 T

Uncoiling width:1200 mm

Inner diameter: 450-550 mm Size of the main part: about 7500 х 1650 х 1500

Weight of main part: 3. 5 tons

Voltage: 240 V/50 HZ 3 Phase or as your required

Roller fixer : middle plate

Frame : 350 mm H beam steel welded

Drive mode: case of differential

Material of rollers: 45# steel, surface hard chromium plating Material of shafts: 45# steel

Diameter of shafts: φ 80 mm

Number of rollers : 13 rollers

Main power: 5.5 kw Payment terms

Payment: 30% T/T in advance and balance 70% after inspection confirmation before shipment.

Delivery:within 45 working days after receipt of deposit. Warranty

1. Two years guarantee, and we will provide the technical support for the whole life.

2. Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day for salary, one technician needed.

4. Training time: one week (contains the time of installation and adjustment)

Except the this,we also supply the Wall Partition Roll Forming Machine.

Mr. Cary xu

Mr. Cary xu